When you’re operating an atomic absorption spectrophotometer, you might observe that many depend on a flame to function. This isn’t a casual decision. It’s a purposeful setup that improves how you examine elements in your materials. Flame-based atomic absorption spectroscopy (AAS) has been a dependable technique for years. It offers you a useful means to gauge metal levels confidently. In this article, you’ll delve into the reasons for employing a flame, its perks, and how it suits your laboratory’s demands. Plus, you’ll get a glimpse at PERSEE as a trustworthy provider.

The Fundamental Role of Flame in AAS

You’ve probably pondered what renders the flame so vital in this procedure. In an atomic absorption spectrophotometer, the flame acts as the core of the operation. It converts your material into a state suitable for evaluation. The goal is to establish ideal circumstances for spotting elements. And the flame manages this job capably. Let’s dissect the main factors that make it essential.

Atomization Process Essentials

Before you dig further, reflect on how your material becomes quantifiable. The flame in an atomic absorption spectrophotometer warms your material to split it into individual atoms. This action is known as atomization. You present your material as a delicate spray. Then, the flame’s warmth evaporates it. This ensures the elements reach a vaporous form primed for study. This phase is critical for obtaining precise readings from your device.

Energy Requirements for Element Excitation

You might wonder what follows. After atomization, the flame supplies the power necessary to energize the atoms in your material. This energizing lets the atoms soak up light at particular wavelengths. Your device then gauges this to calculate element amounts. The flame’s constant energy flow assures you can identify various metals dependably. Thus, it’s a key component of the arrangement.

Key Advantages of Flame Atomization

Now that you grasp the flame’s purpose, you’ll value the gains it delivers to your efforts. Flame atomization provides tangible benefits that can simplify your lab activities. It offers steady output and user-friendliness. This approach aids your analytical objectives efficiently.

Temperature Control and Consistency

Before you probe deeper, consider how steadiness affects your findings. The flame in an atomic absorption spectrophotometer enables you to sustain a regulated heat level during your evaluation. You can tweak the flame to match different elements. This ensures uniform settings. As a result, you get dependable outcomes each time you conduct an experiment.

Sample Introduction Efficiency

You might also see how effortlessly your materials enter the system. With flame atomization, you employ a nebulizer to transform your liquid material into a spray. The flame processes this swiftly. This smooth entry allows you to assess multiple materials faster. Consequently, your workflow keeps progressing without undue pauses.

Broad Element Compatibility

Another feature you’ll find handy is the flame’s adaptability. It performs effectively with a diverse array of elements, from alkali metals to transition metals. This gives you leeway in your tests. Whether you’re examining sodium or copper, the flame adjusts to your requirements. This makes it a favored choice for varied uses.

Flame vs. Alternative Atomization Methods

You may be curious about how flame atomization compares to other approaches. While it’s a common pick, options like graphite furnace techniques exist. Each has its role. Grasping the distinctions helps you determine when a flame-based atomic absorption spectrophotometer suits your lab.

Comparison with Graphite Furnace Techniques

Before picking a technique, think about your needs. Flame atomization handles bigger material volumes rapidly. Meanwhile, graphite furnace methods shine with tinier quantities and finer detection thresholds. You’ll notice flame AAS fits regular assessments well. However, graphite could be more suitable for trace-level tasks needing added sensitivity.

When Flame Atomization is Preferred

You might ask when flame AAS is the smarter choice. If you’re managing high-volume duties or require quick results, the flame technique stands out. It’s also simpler to prepare and upkeep. So, if ease and pace matter to you, flame atomization matches your aims nicely.

Technical Components of Flame AAS Systems

To maximize your atomic absorption spectrophotometer, you’ll want to understand what keeps the flame running smoothly. The technical layout is uncomplicated yet thoughtfully crafted to bolster your analyses. Let’s examine the crucial parts that enable it.

Burner Head Design Considerations

Before tweaking your setup, consider the burner’s function. The burner head in a flame AAS instrument guides the flame. It ensures uniform warming of your material. You can select designs based on your preferences—longer slots for steadiness or shorter ones for certain elements. This gives you command over the process.

Fuel-Oxidant Mixture Optimization

You’ll also need to adjust the flame precisely. The blend of fuel (like acetylene) and oxidant (like air or nitrous oxide) dictates the flame’s heat and traits. By refining this mix, you craft conditions suited to the elements you’re studying. This ensures steady output.

Applications Best Suited for Flame AAS

You’re likely eager to know where flame AAS fits into your tasks. This technique excels in useful, daily applications across multiple areas. From ecological reviews to industrial duties, it’s a solid pick for many of your endeavors.

Environmental Analysis Applications

Before analyzing your materials, picture the options. With a flame atomic absorption spectrophotometer, you can gauge metals in water, soil, or air capably. It’s a helpful tool for tracking contamination levels or meeting ecological guidelines. This aids you in monitoring your surroundings.

Industrial Quality Control Uses

You might also apply it in manufacturing environments. Flame AAS allows you to confirm metal content in raw resources or completed goods. This ensures quality and safety. Whether you’re in mining, production, or food handling, it supports your work to uphold norms efficiently.

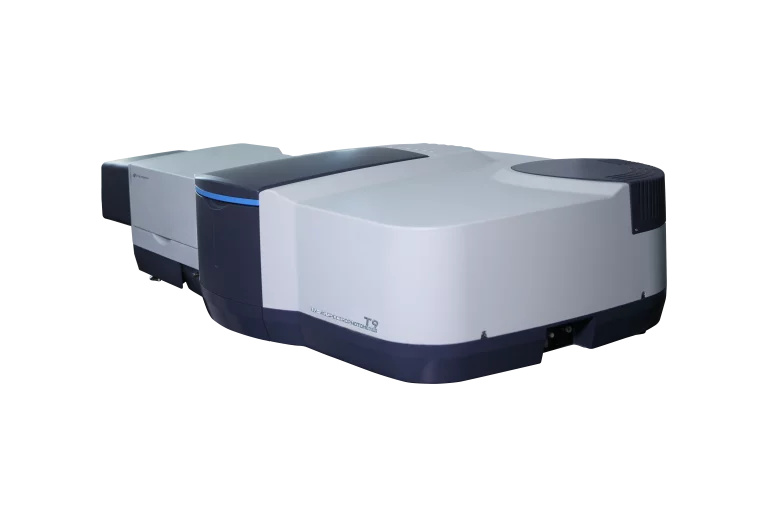

PERSEE: Your Trusted Flame AAS Solution Provider

Once you recognize the worth of flame AAS, you’ll seek a provider you can trust. PERSEE supplies atomic absorption spectrophotometer tailored to your demands, emphasizing quality and assistance. They’re a collaborator worth evaluating for your lab.

Precision Instrumentation for Demanding Applications

Before finalizing your choice, reflect on your needs. PERSEE’s flame AAS instruments are constructed to tackle tough jobs. They offer you dependable output. Their designs include elements that ease your tasks while providing the precision you require.

Global Support and Technical Expertise

You’ll also value the help they extend. PERSEE supports their instruments with practical knowledge and worldwide aid. This ensures you’re never left floundering. Whether you’re configuring or resolving issues, they’re available to assist your success.

FAQs

Q1: Why does flame AAS need a specific fuel mix?

A: You need a particular fuel-oxidant blend to regulate the flame’s heat. This impacts how well your material atomizes and energizes. Adjusting it helps you aim at different elements precisely.

Q2: Can you use flame AAS for all metals?

A: You can apply it to many metals, like calcium or iron. Yet, some, like mercury, might require other techniques due to instability. Flame AAS functions well for a wide span, though.

Q3: How often do you maintain a flame AAS instrument?

A: You’ll keep it fit with routine cleaning and periodic reviews of the burner and nebulizer. PERSEE offers tips to keep upkeep simple. So, it’s not a major burden.