When you’re responsible for guaranteeing the quality and safety of pharmaceuticals, accuracy takes center stage. Atomic absorption spectrometers (AAS) provides a dependable method to examine trace elements and impurities with remarkable precision. This blog investigates how atomic spectrometers accomplish elevated sensitivity determination. It also walks you through their use in pharmaceutical evaluation. From grasping the essential principles to addressing obstacles, you’ll discover why this technology is a worthwhile asset in your collection.

Introduction of Atomic Absorption Spectrometer in Pharmaceuticals

Pharmaceuticals require thorough examination to satisfy safety guidelines, and AAS holds a vital position in this task. Whether you’re inspecting for metallic pollutants or confirming the purity of components, this approach delivers the exactness you seek. Let’s explore how atomic spectrometers function. You’ll also see why they’re appropriate for your pharmaceutical assessment needs.

Atomic absorption spectroscopy employs light to gauge the amount of particular elements in a specimen. You’ll find it especially handy for identifying minute traces of metals that might impact drug safety. By understanding its basics, you can more fully value its contribution to your quality assurance activities.

Principles of Atomic Spectrometer for High Sensitivity

Before you begin operating an atomic spectrometer, it’s useful to comprehend the concepts driving its precision. This section explains the ideas that render AAS efficient for pharmaceutical evaluation.

Understanding Atomic Absorption Mechanisms

The procedure starts when you turn your specimen into vapor and subject it to illumination. Each element takes in light at a distinct wavelength. This allows you to recognize and measure it. This uniqueness is what permits you to notice even small quantities of a material in your pharmaceutical specimens.

By warming your specimen in a flame or furnace, the atoms become liberated to soak up light. You’ll observe how this exchange between light and atoms creates the foundation of AAS. As a result, it provides you with trustworthy information to utilize.

Key Factors Enhancing Sensitivity

Various aspects affect how precise your readings can become. The kind of illumination source, the vaporization technique, and the sensor all contribute. Tweaking these features enables you to adjust your spectrometer for the outcomes you desire.

You’ll also want to think about background adjustment methods. These assist you in reducing disruptions. Consequently, your readings accurately represent the true makeup of your specimen.

Instrumentation of Atomic Spectrometers

Understanding your gear is crucial for obtaining dependable outcomes. This part discusses the instruments you’ll employ. It also explains how they’ve developed to suit your needs in pharmaceutical evaluation.

Core Components and Their Roles

Your atomic spectrometer consists of an illumination source, a vaporizer, a wavelength selector, and a sensor. The illumination source releases wavelengths tailored to the element you’re examining. Meanwhile, the vaporizer converts your specimen specimen into a vapor. You’ll depend on the wavelength selector to single out the correct wavelength. Then, the sensor gauges absorption.

Each piece collaborates to offer you a vivid image of your specimen’s composition. Getting acquainted with these parts aids you in resolving issues and refining your arrangement.

Advances in Spectrometer Design

Technology has enhanced how you utilize atomic spectrometers. Current models provide options like automated specimen management and improved sensors. This makes your evaluation more seamless and productive.

These improvements allow you to handle more specimens in less time while preserving exactness. Keeping up with these developments ensures your lab remains capable and efficient.

Analytical Techniques for Pharmaceutical Analysis

Preparing your specimen correctly and configuring your spectrometer properly are vital steps. Here’s how you can tackle these duties for pharmaceutical testing.

Sample Preparation Strategies

Ready your specimen carefully to secure precise outcomes. You might dissolve tablets, thin out liquids, or break down solids, based on what you’re assessing. Each approach influences how effectively your spectrometer can identify elements.

Focus on preventing contamination at this point. Spotless equipment and cautious handling ensure your data remains credible.

Calibration and Standardization Methods

To rely on your outcomes, you’ll need to adjust your spectrometer. Employing reference solutions with known levels helps you set a standard for comparison.

Frequent adjustments keep your readings steady. You’ll find this action crucial for fulfilling regulatory demands in pharmaceutical evaluation.

Applications in Pharmaceutical Quality Control

With the essentials covered, let’s explore how you can use AAS in your quality assurance routines.

Detecting Trace Elements

Minute metals like lead or copper can slip into pharmaceuticals during manufacturing. Using AAS, you can identify these pollutants at low amounts. This ensures your products remain safe for consumption.

This skill is useful when you’re checking raw materials or completed drugs. It assures you that your supply chain adheres to safety guidelines.

Ensuring Drug Purity and Safety

Beyond pollutants, you’ll apply AAS to verify the purity of active components. Confirming your drug has the correct elements in proper quantities safeguards patients and your standing.

This process connects directly to regulatory adherence. You’ll find it a sensible way to uphold quality across batches.

Challenges and Solutions in High Sensitivity Determination

Even with a strong setup, you may encounter barriers to achieving great sensitivity. This section suggests ways to handle typical problems.

Overcoming Matrix Interferences

Your specimen’s matrix—everything except the element you’re testing—can disrupt readings. Methods like background adjustment or matrix alignment help you lessen these impacts.

Trying out these techniques allows you to polish your approach. You’ll achieve clearer data and more dependable results.

Improving Detection Limits

If you need to spot even tinier amounts, adjusting your vaporization technique or using a stronger illumination source can assist. These changes extend your spectrometer’s abilities further.

Testing various methods reveals what suits your particular specimens. It’s a practical means to boost sensitivity.

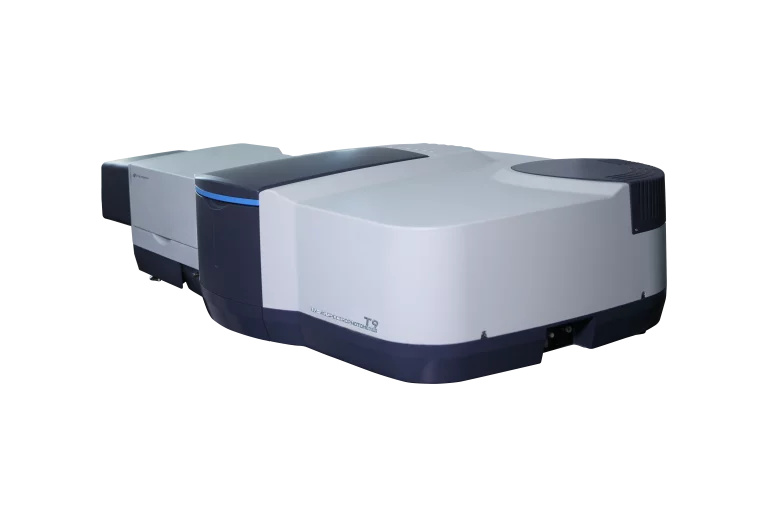

PERSEE: A Trusted Supplier of Atomic Spectrometers

When you’re prepared to acquire an atomic spectrometer, selecting a reliable provider is important. PERSEE emerges as a company you can depend on for quality instruments.

Overview of PERSEE’s Innovative Solutions

PERSEE provides a variety of atomic spectrometers crafted with your requirements in view. Their items feature aspects like easy-to-use designs and strong performance for pharmaceutical evaluation.

Checking out their products offers you choices to fit your lab’s needs. With PERSEE, you’re outfitting yourself with instruments designed for accuracy and dependability.

FAQs

Q: How often should you adjust your atomic spectrometer?

A: You should tweak your spectrometer before each significant testing period or when changing between different specimen types. Routine reviews, like daily or weekly based on your tasks, help sustain precision.

Q: Can atomic absorption spectroscopy identify all elements in pharmaceuticals?

A: AAS works well for many metals and some non-metals, but it’s not ideal for every element. You’ll need to combine it with other methods, like ICP-MS, for a full review if your specimen includes elements AAS struggles to detect.

Q: What’s a frequent error to steer clear of when readying specimens for AAS?

A: A common problem is contamination from unclean tools or careless handling. You can dodge this by using pristine equipment and sticking to strict preparation steps to keep your outcomes trustworthy.