Equipment and Reagents

Equipment:

1. PERSEE atomic absorption spectrophotometer A3F/AFG, equipped with air/acetylene and nitrous oxide/acetylene gas supply, with PERSEE Al hollow cathode lamps. Nitrous oxide/acetylene high-temperature burner head is needed.

2. Stirring hotplate and magnetic bars, capable of heating at 200C

3. Microwave digestion (PERSEE models include: WX-6000, WX-8000, TOPEX+) and TEFLON digestion vessels.

4. Drying oven

Reagents:

1. Aluminum Stock Solution 1000-ppm

2. Nitric acid (m/m=69.2%, ρ=1.42g/cm³)

3. Hydrogen peroxide

4. Pure water

Standard solutions:

Al Standard Solution (Al content 5, 10, 15, 20, 30mg/L): transfer 0.50, 1.0, 1.5, 2.0, 3.0mL of Al Stock Solution 1000-ppm into 100mL volumetric flask, dilute to 100mL with water and mix well. These concentrations can be changed regarding to the concentration in actual samples.

Equipment Condition

Instrument Working Parameters:

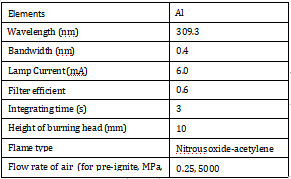

Table 1 Instrumental Parameters

Food Sample Preparation:

Homogenize food samples and take 30g homogeneous sample in drying oven at 85C for 4 hrs

↓

Weigh 0.500 g of dried sample into digestion vessel and add 6 mL nitrous acid & 1 mL hydrogen peroxide. Then, let vessels sit for 10 min to release the gas generated and then cap the vessels carefully.

↓

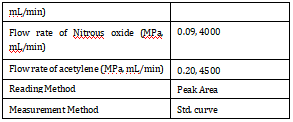

Put vessels into microwave digestion. See the digestion procedures in the table below.

Table 2 microwave digestion procedures

↓

After digestion, put digestion vessels on hotplate at 160 C, until nearly dry. Then, wash vessels several times with pure water and carefully transfer all washing water to 10 mL volumetric flask. Add 0.1 mL nitric acid to keep the acidity of the sample. Then, dilute solution to 10 mL marker with pure water. (do solution blank with same method without adding sample)

↓

Solutions ready for injection

NOTE: Add Potassium (K+) at 2000 ug/mL to inhibit interference. If Si, Ca, P present in sample, add Lanthanum salt solution to reduce the interference.

Experiment Procedure

[igniting nitrous flame]

1. Open nitrous oxide cylinder valve, adjust output pressure to 0.25 MPa, plug in power cable to pre-heat N2O gas for about 15 mins (NOTE: before you install pressure gauge, please loosen the regulating valve of the gauge, and ensure the outlet of the nitrous oxide cylinder is clean).

2. Change the regular burner head to nitrous oxide-acetylene burner head.

3. Start PC, power on instrument and open AAWIN software. Set samples, parameters, standard curves, etc. to designated values. Adjust the height of burner head as in the instrumental parameters.

4. Turn on air-compressor and adjust output pressure to 0.23 MPa. Open acetylene value, set output pressure to 0.09-0.1 MPa.

5. Set acetylene flow rate to 1500 mL/min and ignite for 10 mins to preheat burner head.

6. Set nitrous oxide-acetylene flow rate as in [instrumental parameters] and click “switch” .

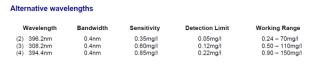

Figure 1 AAWIN software flame switch interface —it’s all automatic and controlled on the software to ensure safety

7. Inject and test standard solutions and sample solutions.

NOTE: due to the high temperature in nitrous oxide flame, we need to scratch away the carbon residue on the burner head every several minutes. For details and online instructions, please contact us by the email address below.

Standard Curve: Al

Apply the Al lamp. Preheat for 30min. Adjust the energy well. Apply instrument parameters as defined in the instrumental parameters

Test the Abs for: Blank solution, Al Standard Solutions (Al concentration of 5, 10, 15, 20, 30mg/L or other concentrations appropriate) and testing solution. Use PERSEE AAS software AAWIN to make standard curve and calculate automatically.

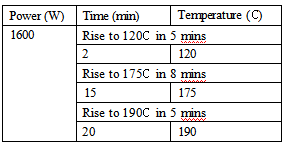

Figure 2 Working range of different wavelengths for testing Aluminum

Results

To ensure a reliable result, try to achieve a linear ratio of over 0.999. The sensitivity of the experiment is high. The detection limits ofAl are 0.50 mg/L.